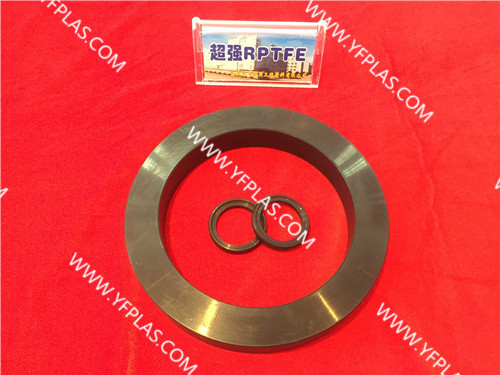

PRODUCT FEATURES:It has solved many problems in the field of chemic

It is composed of tetrafluoroethylene polymer by polymerization, the structure of simple formula -[-CF2-CF2-]n- has excellent chemical stability, corrosion resistance, corrosion resistant material is one of the best in the world, in addition to molten alkali metals, three, five chlorine trifluoride chlorine fluoride solution and fluoride, capable of all other chemicals, in aqua in boiling and is not change, widely used in acid and alkali resistance and organic solvent. A sealing, high viscosity lubrication, electric resistance and good aging resistance, excellent temperature resistant insulation. PTFE itself is not toxic to people.

It has solved many problems in the field of chemical, petroleum, pharmaceutical etc.. PTFE seals, gaskets, gasket, PTFE seals, gaskets, gasket PTFE resin molding polymerization is made of suspension.

High temperature - working temperature up to 250 DEG C.

Low temperature resistance with good mechanical toughness; even if the temperature drops to -196 DEG C, can keep 5% elongation.

The corrosion of most chemicals and solvents, showing the inertia ability of acid alkali, water and organic solvent.

Weather resistance: the bestaging life.

High oil - is a solidmaterialinthe lowestfriction coefficient.

No adhesion is minimal surface tension in solid materials, no adhesion to any material.

No poison, physical inertia, as artificial blood vessels and organs long-term in vivo without adverse reaction.

insufficient

1, PTFE is the flow of "cold". The material products in the long time continuous loads occur plastic deformation (creep), which brings certain restrictions to its application. When PTFE used as a sealing pad, seal tight and the bolts are screwed tightly, so that more specific compression stress, the gasket of "cold flow" (creep) and squashed. These shortcomings can be improved by adding appropriate fillers and other methods to overcome the structural parts.

2, PTFE has outstanding is not sticky, which limits its application in industry. It is an excellent anti sticking material, the properties of surface and other items and make it extremely difficult to bond.

3, PTFE line expansion coefficient is 10~20 times that of steel, than most plastics, the linear expansion coefficient of variation with the temperature change is very irregular. In the application of PTFE, if not pay enough attention to the performance, it is easy to cause loss.

The PTFE material is due to its characteristics as the most commonly used valve soft sealing material, but it also limits its use, so in the application, often according to the actual conditions by filling different formulations (RPTFE) or the import of modified PTFE, the formula and a variety of imported brands, but also the most application widely.

NEXT PRODUCT: LAST ARTICLE

CONTACT

MOREEmail:yfplas@vip.163.com

Mobile :+86-15858755653

Te l :+86-0577-86638259

Whatsapp : 0086-158 5875 5653

Fax :0577-86621759